Fire safety and protection are more prevalent than ever before. There is a huge push on competency and compliance for the installation and products in the fire industry in 2022, following tragic recent events such as Grenfell.

Fire safety and protection are more prevalent than ever before. There is a huge push on competency and compliance for the installation and products in the fire industry in 2022, following tragic recent events such as Grenfell.

Just like a plumber would need to showcase that they are competent to service a boiler, the demand for fire protection installers to show they are competent is essential.

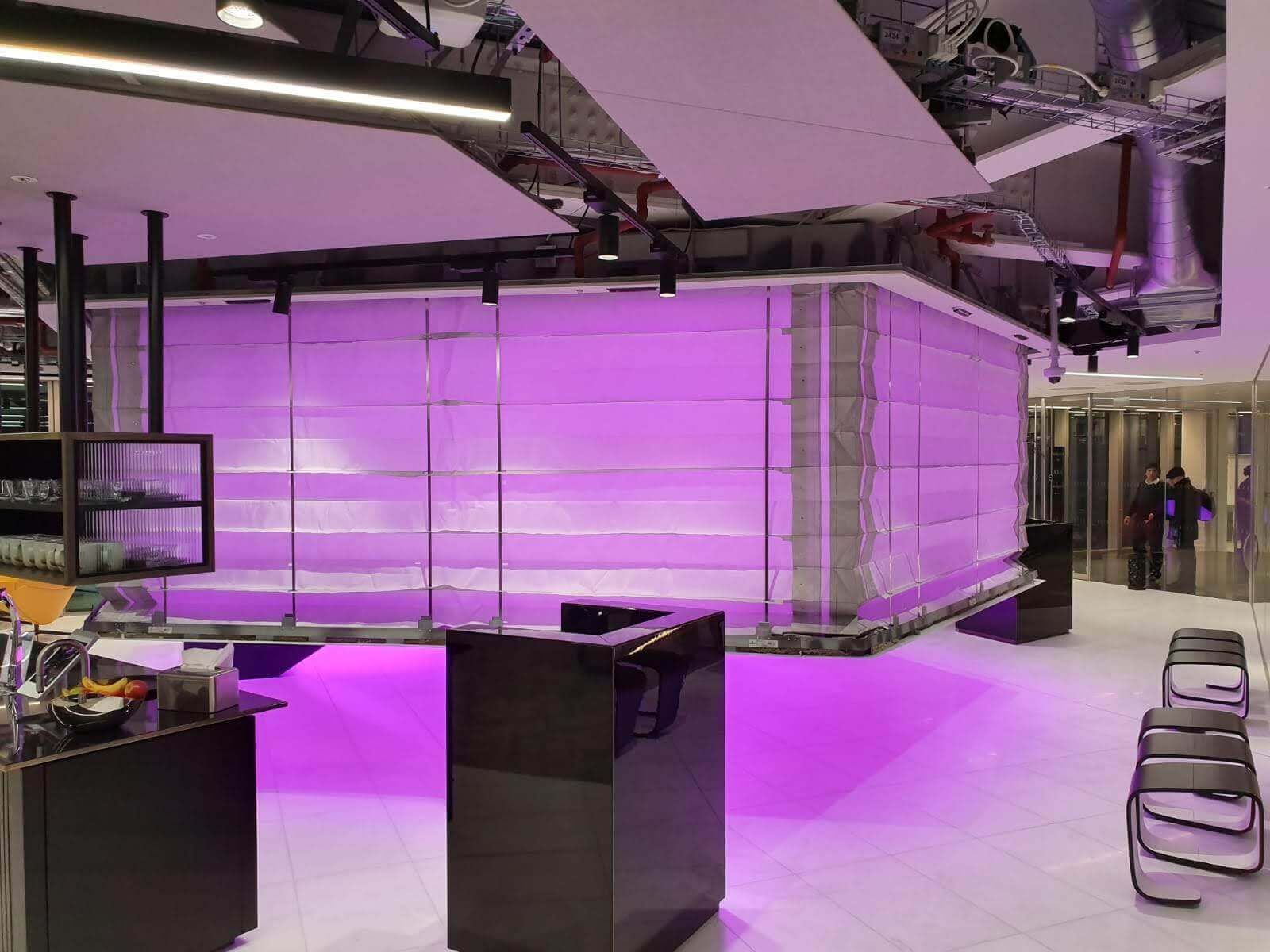

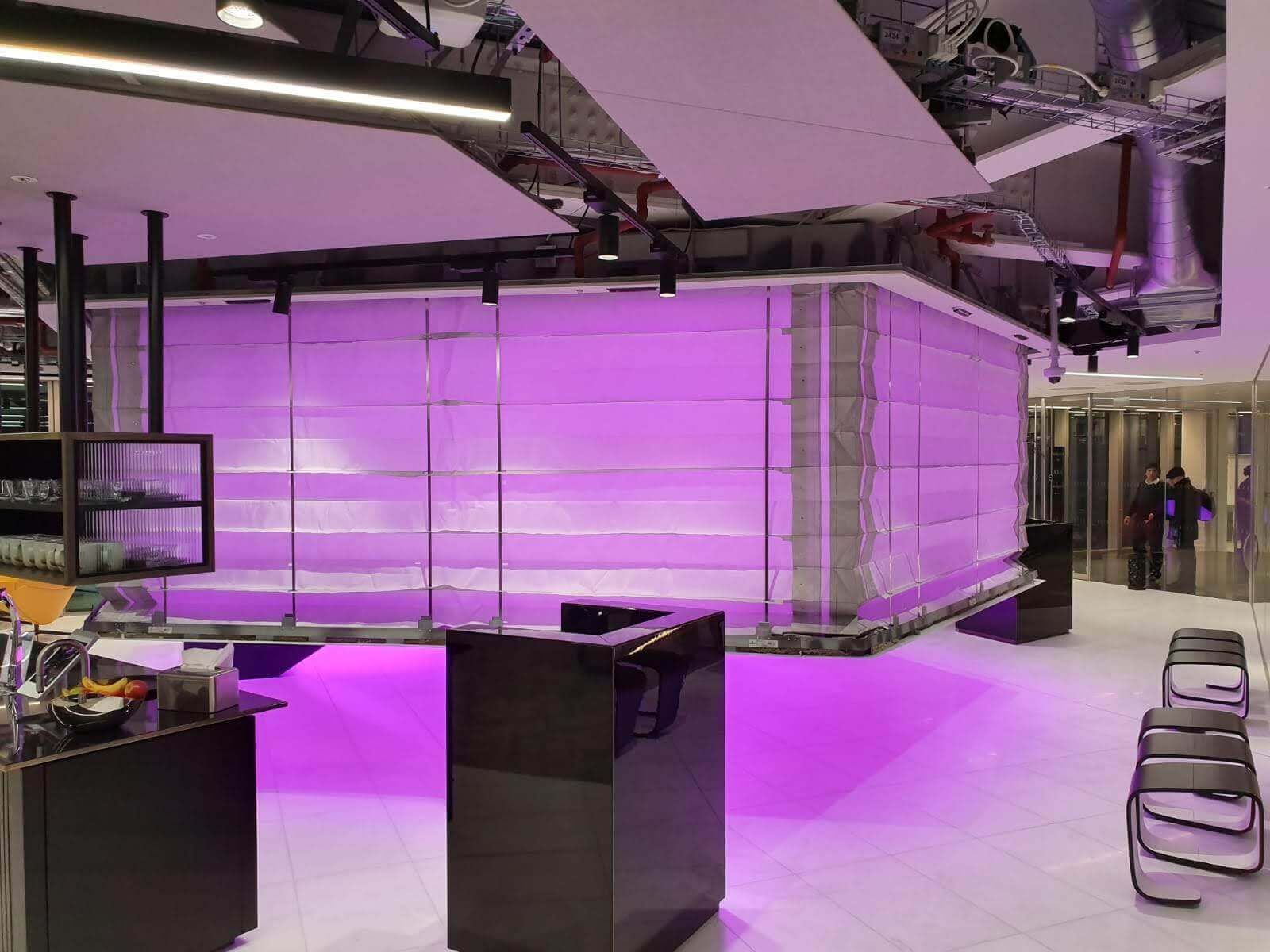

Passive fire protection (PFP) is a crucial component of any fire safety strategy, responsible for safeguarding people and buildings from fire and smoke. Passive fire protection works by

According to Global Market Insights, the passive fire protection market is estimated to be worth $31 billion by 2026. Passive methods are designed to work without the need for human intervention or any external energy reliance and allow for a smooth evacuation process by compartmentalising the fire for as long as possible until the emergency services arrive.

Passive fire protection is something that is considered early on in the design of the building. Contractors, project managers, engineers, structural engineers and more roles are involved in the process.

The UK calls for passive fire protection to meet Building Regulations, which ensures the safety of occupants and visitors and the overall structure of the building. The responsibility of undertaking regular fire risk assessments lies with building owners, managers, and building designers, which includes passive fire protection evaluation.

BS 8524 is the first unique product standard in the world relating solely to active fire curtain barrier assemblies. The standard is split into two parts; BS 8524-1 (Specification) and BS 8524-2 (Code of practice for application, installation and maintenance).

Both parts provide comprehensive guidance to specifiers, manufacturers, installers, building inspectors and buyers, with information about the manufacturing of a fire curtain product, how it is installed and its ongoing service and maintenance.

BS 8524 is the only global fire curtain standard and supersedes PAS 121: 2007. Third-party certification is required for this standard, and both parts are important to consider. The certification provides certainty to end-users and building occupiers that the product has passed in-depth third-party testing against a set of strict standards and criteria.

The former fire curtain specification, PAS 121:2007, was overtaken by BS 8524 in April 2013. BS 8524 covers the entire system, and to be fully compliant fire curtains must have passed all required testing.

Part 1, the specification for active fire curtain barriers, provides information, requirements and guidance on how to test for each aspect of the standard. It can only be achieved if all nine annexes, of which it comprises, are satisfied and approved by a third-party certification body. Annex G, for example, outlines the testing method for motor operation, which involves placing it at elevated temperatures, and at maximum loads following a prescribed timeline heat curve for a specified number of cycles.

Part 2 provides a code of practice for the application, installation and maintenance of fire curtains. The annexes it consists of include guidance on installation checklists, commissioning, as well as maintenance. For example, the comprehensive Inspection Checklist in Annex F details the requirement for the curtain to descend into a ‘closed’ position at the required descent speed when the power cable to the control panel is disconnected. This proves the gravity fail-safe mechanism works and can maintain the required descent speed as dictated by the standard.

BS 8524-1 is a rigorous and complex test standard and is specific only to fire curtain barriers. It, therefore, provides less ambiguity between this standard and other passive fire protection product standards e.g. BS EN 1634-1

The numerous annexes (A to I) and references that MUST be completed to be fully compliant with BS 8524-1 include the following:

• Annex A (normative) Overlapping multiple barriers

• Annex B (normative) Order of testing

• Annex C (normative) General requirements for testing

• Annex D (normative) Test method for barrier assembly reliability and response

time and the durability of materials

• Annex E (normative) Test method for the durability and reliability of alternative or

additional motors

• Annex F (normative) Calculation of ambient temperature smoke leakage

• Annex G (normative) Test method for the reliability of motor operation at elevated

temperatures

• Annex H (normative) Test method for ancillary and optional equipment

• Annex I (informative) Typical product performance summary

BS 8524 is designed to be a fully ratified and audited product, installation and service scheme. The standard ensures through periodic audits that the provenance of the product’s components is the same as those that were tested originally. Installations are also picked at random for site visits for compliance with best practices.

• International Fire Consultants (IFC) offer a UKAS approved BS 8524 full third party certification scheme through IFC Certification

• It is important that both BS 8524-1 and BS 8524-2 are supported by the third party scheme provider

• Always ask the product manufacturer and installer for their BS 8524-1 and BS 8524-2 certification

ISO 21524 is the new international standard for fire curtains. This new international standard builds on many of the aspects within BS 8524-1 and BS 8524-2; enhancing some of the requirements and introducing new features such as pass doors and vision panels. There is also a new requirement to include repair patches to tears in the fabric.

The forthcoming new release of BS 8524-1 and BS 8524-2 refers to ISO 21524 for the test method of the new features and in some cases making further improvements.

Coopers Fire has worked closely with IFC Certification Ltd to ensure compliance with BS 8524 Parts 1 & 2 and IFC Certification has been accredited by UKAS to issue third party certification for this standard.

If you would like to learn more about our BS 8524 Fire Curtains, feel free to contact us at 02392 454 405 or email us.

Feel free to check out our other products too!